Process Flow

Pipe Line Process map

Category

Process

Process Description

1st Forming

For easy assembly of PIPE with counterparts such as hoses and processed products, the ends are formed and processed into the shape of connector birds

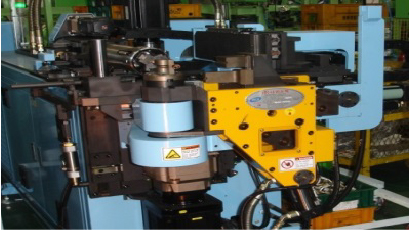

Banding

Bending the pipe into a predetermined shape and curvature radius.

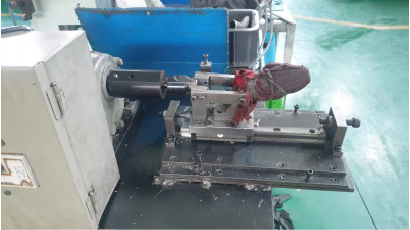

CUTTING

Cutting the bent pipe, which has been processed into a predetermined shape, according to the specified specifications in the drawing or other guidelines.

Roundness Correction

A forming process to ensure the cut surface of the pipe maintains an accurate circular shape.

DEBURRING

A smoothing process for the cut surface using tools such as a brush, bite, or paper.

Category

Process

Process Description

2nd Forming

Processing the opposite side of the primary forming to shape the end for easy assembly with the counterpart component.

Welding

Welding process to join the processed pipe and bracket

Cleaning

Ultrasonic cleaning to remove oil and foreign substances from the inner and outer surfaces of the pipe

Assembly

Assembling and press-fitting the PIPE ASSEMBLY with the counterpart component

Packaging and Shipment

Packaging the pipes into boxes according to the delivery unit